Matthew323

Well-Known Member

- Joined

- Feb 15, 2020

- Messages

- 1,428

- Reaction score

- 1,477

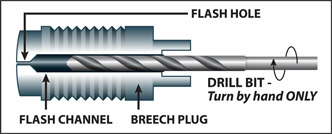

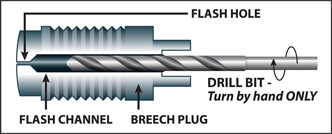

What quality of drill bit do you purchase to clean out the hard carbon deposits from Blackhorn209 combustion in your rifle's/pistol's breech plug?

Do you just purchase the El Cheapo ones from Harbor Freight, or do you opt for a more expensive cobalt drill bit?

I am going to need to purchase a supply of drill bits for the Lehigh Defense QRBP Breech Plug for my CVA Optima V2 pistol.

Thanks,

Bruce

Do you just purchase the El Cheapo ones from Harbor Freight, or do you opt for a more expensive cobalt drill bit?

I am going to need to purchase a supply of drill bits for the Lehigh Defense QRBP Breech Plug for my CVA Optima V2 pistol.

Thanks,

Bruce